In the construction industry, there are different materials that are commonly used for various purposes. One important consideration is whether to use LVL beams or traditional timber. Understanding the differences between these materials is crucial for making the right choice for your project. Let’s dive into the world of LVL beams and traditional timber to explore their characteristics, manufacturing processes, key differences, applications, and factors to consider when deciding which one to use.

Understanding LVL Beams and Traditional Timber

Before we delve into the details, let’s define what LVL beams and traditional timber actually are.

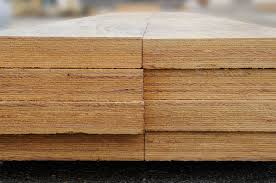

When it comes to structural components in construction, LVL beams and traditional timber play crucial roles. Laminated Veneer Lumber (LVL) beams are engineered wood products made from thin wood veneers glued together. These veneers are carefully selected and arranged in a parallel pattern to maximize strength and minimize defects. LVL beams are favored for their exceptional strength-to-weight ratio, making them ideal for supporting heavy loads in various construction applications.

Defining LVL Beams

Laminated Veneer Lumber (LVL) beams are structural components made from thin wood veneers glued together. The veneers are arranged in a parallel pattern, resulting in a strong and durable engineered wood product. LVL beams are known for their excellent strength-to-weight ratio, making them a reliable choice for supporting heavy loads in construction projects.

On the other hand, traditional timber refers to solid pieces of wood that are cut from trees and used in construction. This age-old material has stood the test of time and is renowned for its natural beauty and versatility. Traditional timber offers a classic aesthetic appeal that is hard to replicate with modern materials, adding a touch of warmth and character to any structure.

What is Traditional Timber?

Traditional timber, on the other hand, refers to solid pieces of wood that are cut from trees and used in construction. It has been used for centuries and is known for its natural beauty and versatility. Click here to learn more about natural beauty.

The Manufacturing Process of LVL Beams and Traditional Timber

The process of manufacturing LVL beams differs from the creation of traditional timber. Let’s take a closer look at each.

How LVL Beams are Made

LVL beams are manufactured by peeling logs into thin veneers. These veneers are then dried and glued together under high pressure to create a single piece. The resulting beam is strong, uniform, and free from defects typically found in natural solid timber. This manufacturing process ensures consistent quality and performance in LVL beams.

One interesting aspect of the LVL beam manufacturing process is the use of adhesives. The adhesive used to bond the veneers together is a critical component in ensuring the structural integrity of the final product. Different types of adhesives, such as phenol-formaldehyde or polyurethane, may be used depending on the intended application of the LVL beams. The precise application and curing of the adhesive are essential steps in creating a durable and reliable LVL beam.

The Creation of Traditional Timber

Traditional timber is sourced by cutting trees into logs. The logs are then sawn into boards or beams, which are used in construction. The timber is typically subjected to drying and seasoning processes to reduce moisture content and enhance its structural stability. The final product retains the natural characteristics and unique grain patterns of the wood. Learn more about moisture content at https://people.umass.edu/~mcclemen/581Moisture.html

One fascinating aspect of traditional timber production is the utilization of sustainable forestry practices. Responsible forestry management ensures that trees are harvested in a way that promotes forest regeneration and biodiversity. By selectively cutting trees and replanting new ones, traditional timber production can be environmentally friendly and support the long-term health of forest ecosystems.

Key Differences Between LVL Beams and Traditional Timber

Now that we understand the basics of LVL beams and traditional timber, let’s examine the key differences that set them apart.

Strength and Durability Comparison

LVL beams are engineered to be significantly stronger and more durable than traditional timber. The manufacturing process of LVL beams ensures consistent strength properties, allowing for greater load-bearing capacity. In contrast, solid timber can have variations in strength due to natural defects and inconsistencies in the wood’s structure.

But what exactly makes LVL beams so strong and durable? The answer lies in their construction. LVL stands for Laminated Veneer Lumber, which means that multiple layers of wood veneers are glued together with the grain of each layer running in the same direction. This construction method eliminates the weaknesses found in solid timber, such as knots or splits, making LVL beams more reliable and resistant to bending or warping over time.

Cost Differences

When considering cost, LVL beams and traditional timber have different price points. LVL beams tend to be more expensive upfront due to the manufacturing process involved. However, their durability and reduced risk of warping or twisting can result in long-term cost savings by minimizing maintenance and replacement expenses.

Additionally, LVL beams offer another cost-saving advantage: their ability to span longer distances. Due to their superior strength, LVL beams can support larger spans without the need for additional support columns or beams. This not only reduces material and labor costs but also allows for more open and flexible floor plans in construction projects.

Environmental Impact

The environmental impact of using LVL beams versus traditional timber is another important aspect to consider. LVL beams are typically made from fast-growing plantation trees, which can be sustainably managed. These trees are specifically grown for the purpose of producing engineered wood products like LVL beams, ensuring a renewable and responsible source of material.

On the other hand, traditional timber comes from natural forests, where unsustainable logging practices can have a significant ecological impact. Clear-cutting, illegal logging, and habitat destruction are some of the consequences associated with the extraction of timber from natural forests. By choosing LVL beams, you can contribute to reducing deforestation and promoting more environmentally friendly construction practices.

In conclusion, while LVL beams may have a higher upfront cost, their superior strength, durability, and environmental benefits make them a compelling choice for construction projects. By investing in LVL beams, you not only ensure the structural integrity of your building but also contribute to a more sustainable future.

Applications of LVL Beams and Traditional Timber

Now that we have explored the differences between LVL beams and traditional timber, let’s discuss their ideal applications in construction.

When it comes to LVL beams, their exceptional strength and reliability make them a top choice for various structural applications. These beams are commonly found in modern construction projects where durability and load-bearing capacity are crucial. In addition to their use as floor beams, roof beams, headers, and beams in load-bearing walls, LVL beams are also favored in the manufacturing of doors, windows, and sturdy furniture pieces. Their uniformity and resistance to warping or twisting make them a reliable option for projects requiring long, straight spans.

Where to Use LVL Beams

LVL beams are popularly used in structural applications that require high strength and reliability. They are commonly used for floor beams, roof beams, headers, and beams in load-bearing walls. LVL beams also find applications in the manufacturing of doors, windows, and furniture.

On the other hand, traditional timber stands out for its versatility and timeless aesthetic appeal, making it a preferred choice for a wide array of applications. Beyond its structural uses in framing walls, floors, and roofs, traditional timber is often selected for its natural beauty in interior finishes, furniture crafting, and decorative elements. The warmth and character of traditional timber add a touch of authenticity to any space, whether it’s a cozy cabin retreat or a contemporary urban loft.

Ideal Uses for Traditional Timber

Traditional timber offers versatility and aesthetic appeal, making it suitable for a wide range of applications. It is often used for framing and construction of walls, floors, and roofs. Additionally, traditional timber is a popular choice for interior finishes, furniture, and decorative elements.

Making the Right Choice: LVL Beams or Traditional Timber?

Deciding between LVL beams and traditional timber requires careful consideration of various factors. Let’s explore what you should keep in mind when making this important choice.

Factors to Consider

When choosing between LVL beams and traditional timber, consider factors such as the structural requirements of your project, the desired aesthetics, the budget constraints, and the environmental impact. Each material has its own advantages and disadvantages, so it’s important to assess your specific needs before making a decision.

Pros and Cons of Each Material

It’s helpful to weigh the pros and cons of LVL beams and traditional timber to make an informed choice. LVL beams offer superior strength, durability, and consistency but come at a higher upfront cost. Traditional timber has a natural beauty, is more cost-effective in the short term, but may require additional maintenance.

However, it’s worth noting that LVL beams have an edge when it comes to sustainability. LVL beams are manufactured from fast-growing, renewable plantation timber, making them a more environmentally friendly option compared to traditional timber, which often involves the harvesting of old-growth forests. So, if reducing your carbon footprint is a priority, LVL beams might be the way to go.

On the other hand, traditional timber has a timeless charm that can add character and warmth to any project. Its natural grain and texture create a unique aesthetic that is hard to replicate with engineered materials. Additionally, traditional timber can be easily customized and shaped to fit specific design requirements, allowing for greater design flexibility.

Ultimately, the choice between LVL beams and traditional timber depends on the specific requirements of your project and your priorities. It’s always recommended to consult with architects, engineers, or construction professionals to ensure that you make the best decision for your construction needs.

In conclusion, understanding the characteristics, manufacturing processes, key differences, applications, and factors to consider will guide you in comparing LVL beams to traditional timber. Whether you prioritize strength, durability, cost, or environmental impact, making an informed choice will help you achieve the desired results for your construction project.

Remember, the choice between LVL beams and traditional timber is not one to be taken lightly. It’s an investment in the future of your project, and considering all the relevant factors will ensure that you make the right choice. So take your time, do your research, and consult with professionals to make an informed decision that will lead to a successful and satisfying construction project.

Other resources: An Overview of LVL Construction Benefits and Applications